How Does It Work

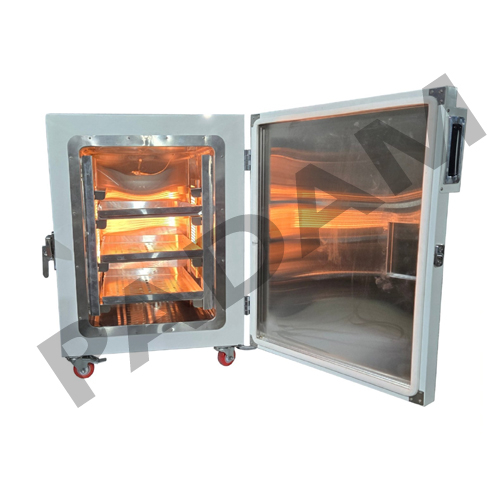

- Infrared heaters emit IR waves.

- These waves penetrate the surface of the material.

- Energy is absorbed and converted into heat within the material itself.

- This evaporates moisture from the inside-out or surface-down, depending on the wavelength.