Types of Industrial Furnaces

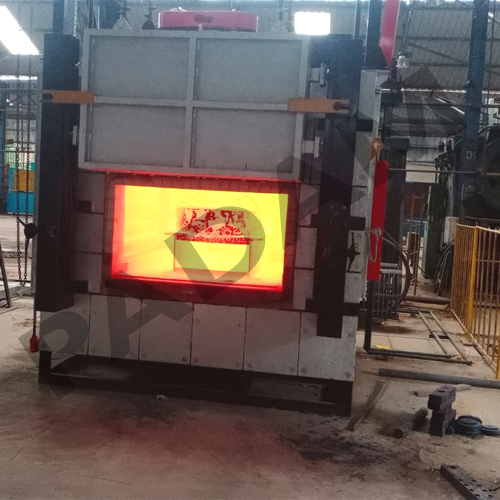

- Box Furnace (Batch Furnace)

- Used for heat treatment, annealing, and hardening of metals.

- Operates in batch mode, heating materials placed inside a chamber.

- Ideal for steel, aluminum, and alloy processing.

- Conveyor Furnace (Continuous Furnace)

- Designed for high-volume production.

- Uses a moving conveyor belt for continuous material processing.

- Common in powder metallurgy, brazing, and ceramics.

- Rotary Furnace

- Features a rotating drum to process bulk materials evenly.

- Used for metal refining, recycling, and calcination.

- Ideal for lead, aluminum, and cement industries.

- Induction Furnace

- Uses electromagnetic induction to heat and melt metals.

- Provides rapid and energy-efficient melting.

- Common in steel, foundry, and casting industries.

- Induction Furnace

- Uses electromagnetic induction to heat and melt metals.

- Provides rapid and energy-efficient melting.

- Common in steel, foundry, and casting industries.