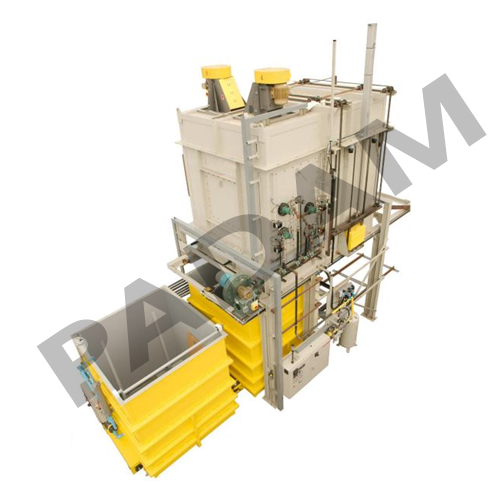

Components Breakdown

- Heating Chamber: For soaking metal at precise temperatures.

- Drop Bottom Door Mechanism: Opens quickly to release load.

- Hoist or Elevator: Moves the load vertically into quench tank.

- Quench Tank: Cooled and sometimes agitated for uniform quenching.

- Control Panel: For managing temps, times, movement, and logging.