Types of Bell Furnaces

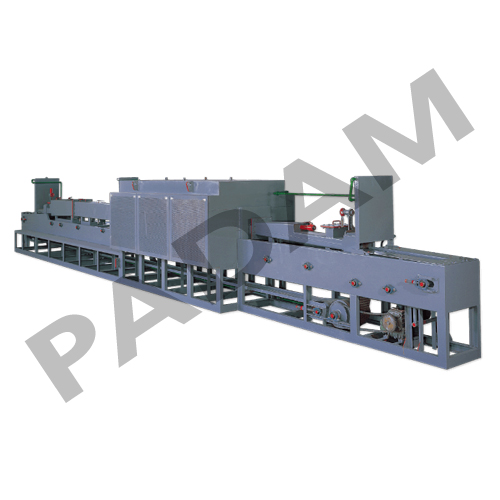

- Continuous Bright Annealing Furnace

- Uses a conveyor, roller hearth, or mesh belt to transport materials.

- Ideal for high-volume processing of metal strips, tubes, or wires.

- Batch-Type Bright Annealing Furnace

- Designed for individual loads that require controlled processing.

- Used for large workpieces, coils, and sheets.

- Vacuum Bright Annealing Furnace

- Uses a vacuum chamber to eliminate oxidation and contamination.

- Best for high-precision alloys, aerospace, and medical applications.

- Hydrogen Bright Annealing Furnace

- Uses pure hydrogen gas (H2) as the protective atmosphere.

- Provides the highest-quality bright finish with no oxidation or discoloration.